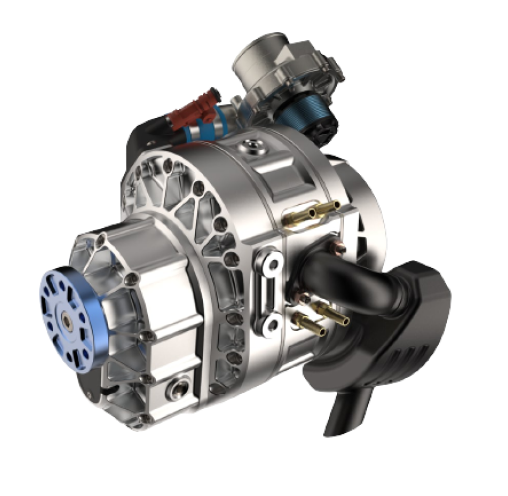

Highly effective for sustained operation at constant speeds. Built for airplane-type UAVs with high electrical loads and VTOLs.

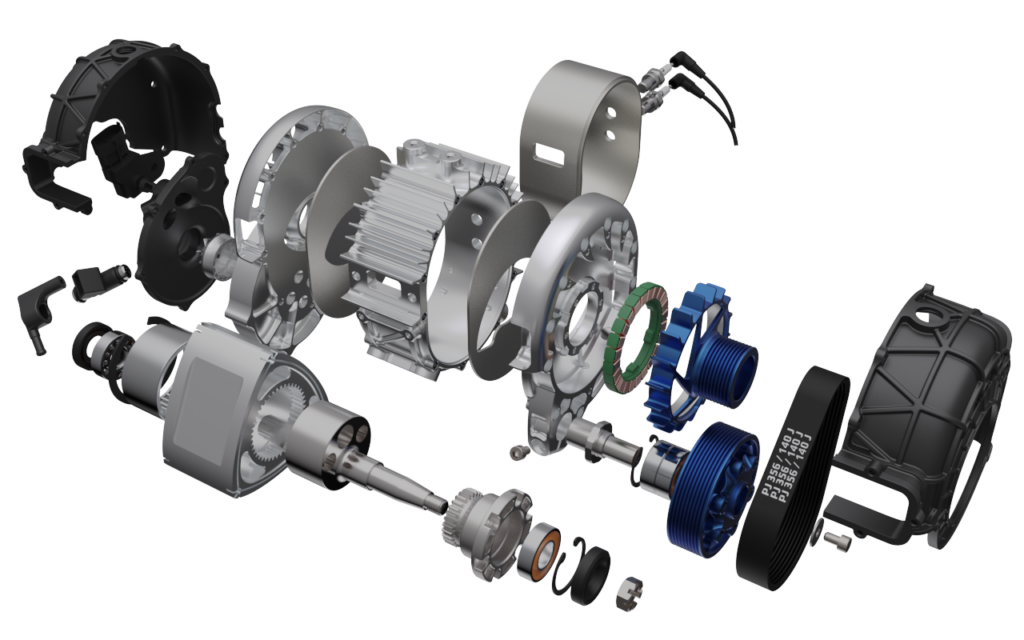

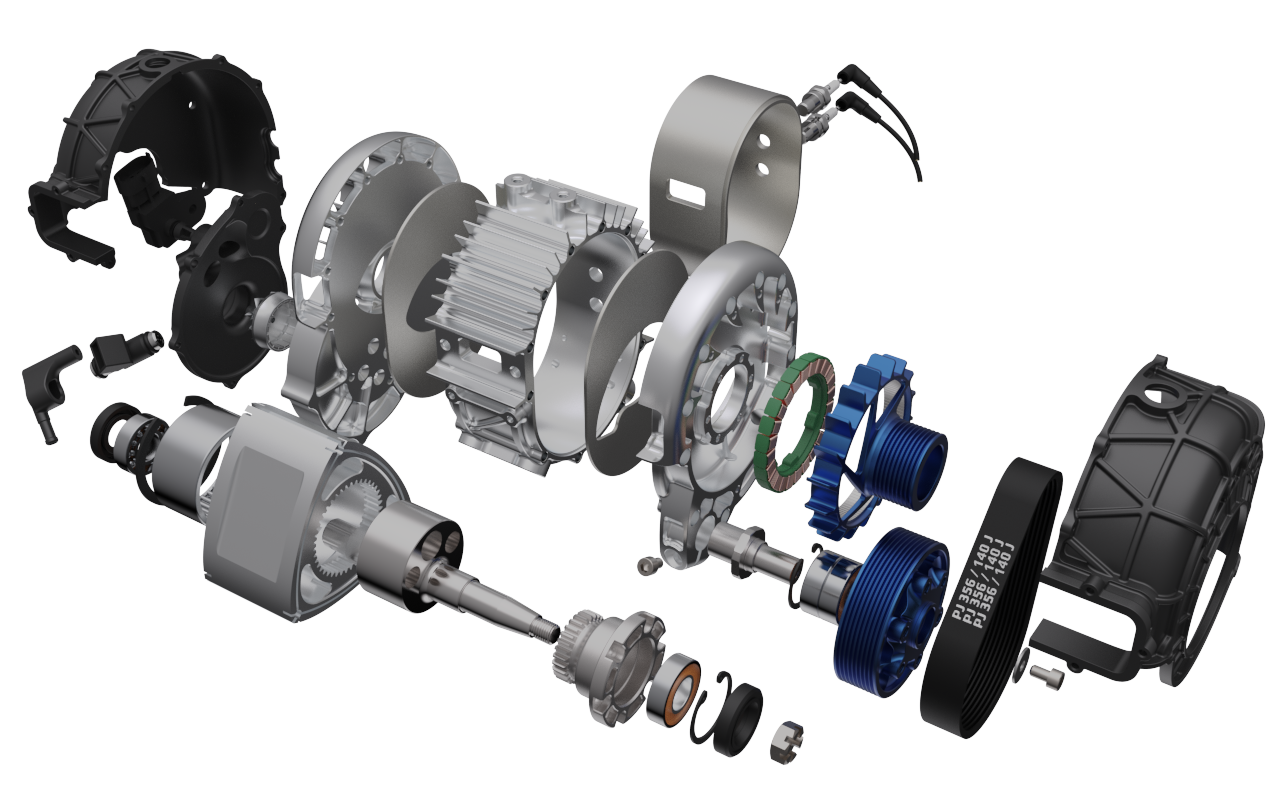

- Fuel System: Our RW79 engine features a cutting-edge electronic fuel injection system that crafts the fuel-air mix via rotor injection. This mix is then sped up by centrifugal force right into the combustion chamber. To maintain the perfect intake pressure no matter the conditions, we’ve added an electrically driven supercharger, powered by a compact turbine and regulated by the engine control unit (ECU) for precision. Plus, our unique ultrasonic fuel injectors adjust their operation to keep fuel droplet sizes uniform, ranging from 2 to 5 nanometers, under various temperatures and altitudes.

- The RW79P stands out with its steady electrical power delivery of 2 kW, and peak performance reaching up to 3 kW, offering a reliable power source. It features a distribution controller that divides power across four separate groups, each with four channels, making up a total of 16 channels operating at 48V. Users have the flexibility to merge these channels into groups of 96, 144, 192, or 384 volts, catering to various power needs. Each group of channels allows for independent operation, including priority-based overload protection, power balancing, and limitations, guaranteeing both top-notch performance and safety.

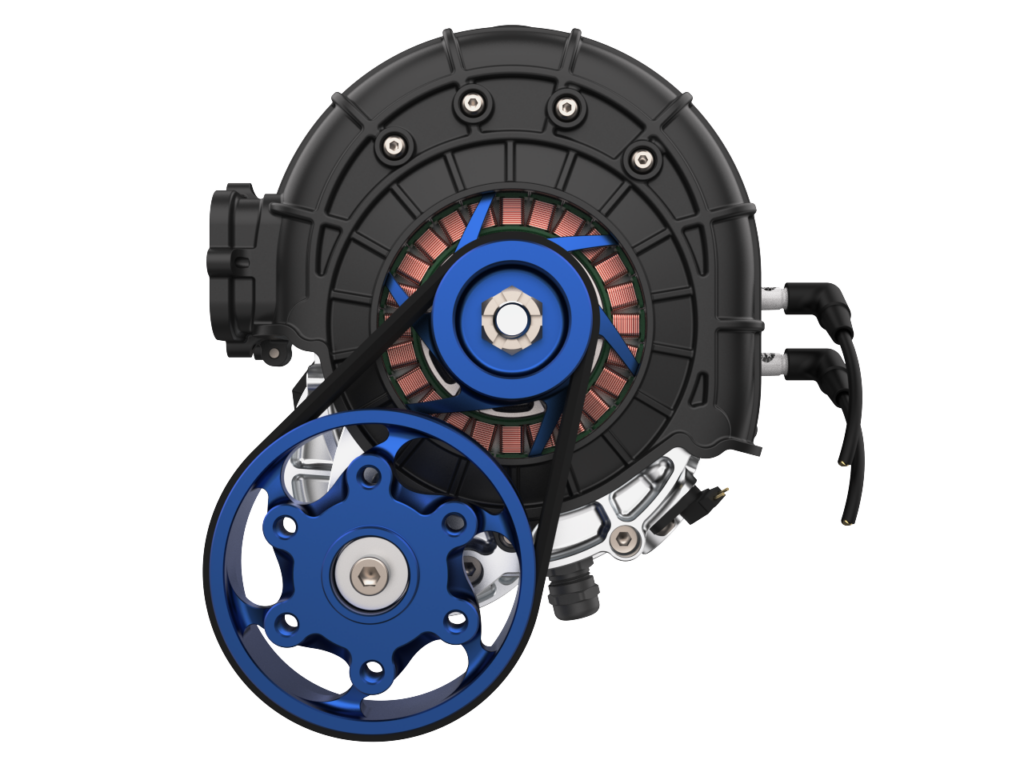

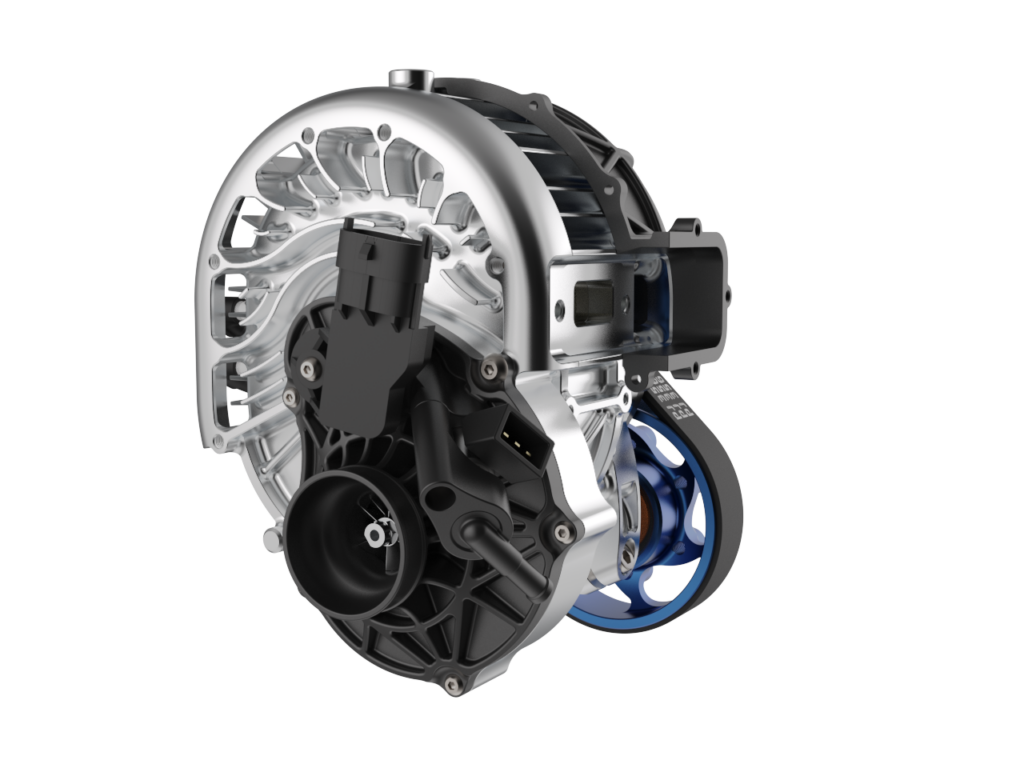

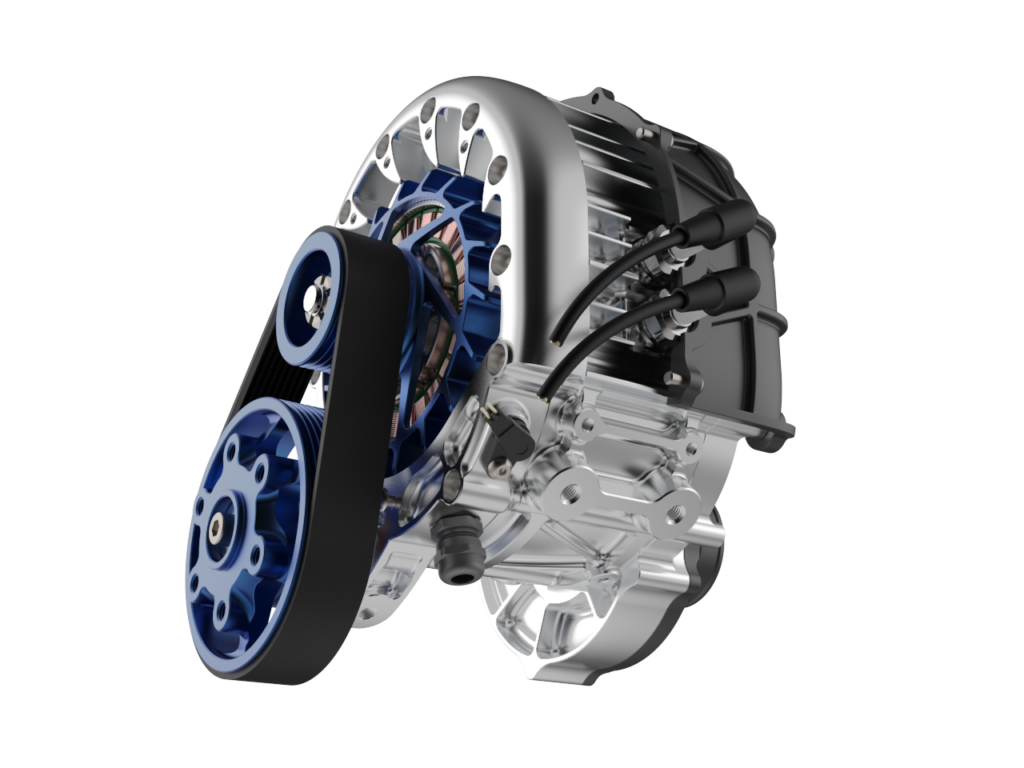

- Cooling System: We use a forced air cooling approach. Air is pulled in to cool the generator’s electric coils, then swiftly moved across the rotor’s centrifugal blades and through specially designed channels in the engine housing. This design efficiently manages the heat, especially the uneven heat distribution common in Wankel engines. The air exits around the exhaust system, minimizing heat within the engine space and blending with exhaust gases to lower infrared (IR) visibility, enhancing stealth.

- Materials and Technologies: Our engine’s casing is precisely crafted from dural alloy using CNC milling, ensuring high durability and precision. The combustion chamber features a cast-iron sleeve and side walls, with innovative labyrinth cooling channels on the reverse side for efficient heat management. The rotor, designed for optimal cooling, is hollow and crafted from aluminum forging. For enhanced durability, apex channels are electroplated, apex seals are made of tough tungsten carbide, and sidewalls are finely ground and treated with an anti-seize coating. The crankshaft and gears are made from high-strength forged steel, while bearings glide on polished and hardened surfaces for reliability. The engine’s exterior is protected with hard anodizing and primer for extra durability, with all fasteners crafted from stainless steel or titanium to withstand the elements. Electrical connections meet military specifications for robustness and are fully sealed for maximum reliability.

| Engine type | Wankel, Rotary hybrid. |

| Weight | 4.9 kg |

| Displacement | 79cc |

| Length/Width/Height | 162x177x193 mm |

| Power | 22 hp at 13000 rpm |

| Maximum Continuous Speed | 13000 rpm |

| Ignition | Twin spark plug. Variable ignition front. IonSence |

| Cooling | Forced Air |

| Fuel system | Throttleless Two Stage Fuel Injection. eSupercharger |

| Fuel type | Heavy fuel, Aviation kerosine JET-A1, JP5, JP8 |

| Specific Fuel Consumption (cruise) | 240 – 260 g / kWh |

| TBO (estimate) | 1000 hours |

| Preferred oil type | API TC |

| Sensors / Telemetry | EGT – Exhaust gas temperature; CHT – Cylinder head temperature; IAT – Intake air temperature; RPM – Rotation per mine; CSP – Crankshaft Position; KS – Knock sensor; Airflow, Fuel Flow |

| Control | Ethernet, CAN 2.0B J1339/29bit; RS485/Modbus, ADLM + TrueTorque |

| Electric System | 14.4/28/48VDC Internal alternator / starter; Internal starter battery pack 5Ah |

| Electric output, Volts | 48/96/144/192V |

| Output electric groups/channels | 4/16 |

MSRP: 15500 Euro (FOB Barcelona)

Our “Developers Kit” includes an engine mounted on a subframe, designed for easy installation on a dyno. This comprehensive kit comes with everything needed for development: a set of radiators, pumps, a complete fuel system, an Engine Control Unit (ECU), and a wiring kit. Additionally, we provide detailed software control documentation, including an Application Programming Interface (API) and the necessary source codes, to facilitate seamless integration and customization.

Shipping from Barcelona, Spain. Brutto 20kg, 0,7m3.

Please fill in the form below or contact us using the details at the bottom of the page